Subcontract CNC machining has become a popular choice for companies looking to achieve high precision and consistency in their manufacturing processes. CNC machining offers a level of accuracy and repeatability that is difficult to achieve with traditional machining methods. By outsourcing their machining needs to a specialized subcontractor, companies can benefit from cutting-edge technology and expertise without the need for significant investment in equipment and training.

Precision and Complexity in CNC Machining

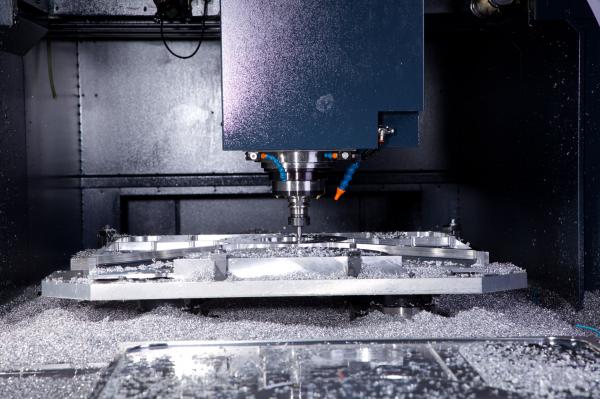

One of the key advantages of subcontract CNC machining is the ability to produce intricate and complex parts with tight tolerances. CNC machines are capable of performing a wide range of operations, from drilling and milling to turning and grinding, with a level of precision that is unmatched by manual methods. This makes them ideal for manufacturing components that require high levels of accuracy, such as aerospace parts, medical devices, and automotive components.

Consistency in Production

In addition to precision, subcontract CNC machining offers consistency in production. CNC machines are programmed to follow exact specifications, ensuring that every part produced is identical in quality and dimensions. This level of consistency is essential in industries where even the slightest variation can have a significant impact on performance and safety. By outsourcing their machining needs, companies can ensure that each part meets the highest quality standards, resulting in improved product performance and customer satisfaction.

Flexibility and Scalability

Furthermore, subcontract CNC machining offers flexibility and scalability to meet changing production demands. Companies can easily adjust production volumes and schedules without the need for significant downtime or retooling. This flexibility allows companies to respond quickly to market fluctuations and customer demands, helping them stay competitive in today’s fast-paced manufacturing environment.

Access to Specialized Expertise and Technology

Another benefit of subcontract CNC machining is the ability to access specialized expertise and technology. CNC machining subcontractors invest in state-of-the-art equipment and training to stay at the forefront of industry advancements. By partnering with a reputable subcontractor, companies can leverage this expertise to improve their manufacturing processes and achieve superior results.

Conclusion

Overall, subcontract CNC machining offers numerous advantages for companies seeking high precision and consistency in their manufacturing operations. By outsourcing their machining needs to a specialized subcontractor, companies can benefit from advanced technology, expertise, flexibility, and scalability, all without the need for significant capital investment. Whether producing complex aerospace components or simple automotive parts, subcontract CNC machining can help companies achieve the highest quality standards and improve their overall manufacturing performance.