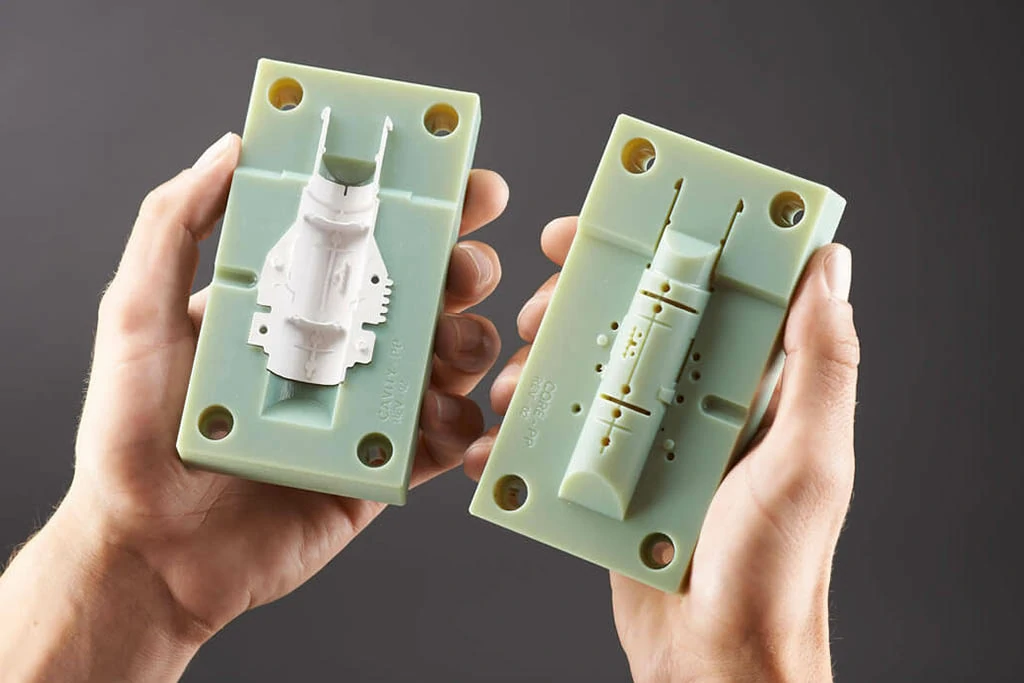

When it comes to manufacturing high-quality, durable components, having expert custom mold manufacturing is crucial. Custom injection molds are designed to meet specific manufacturing requirements, providing tailored solutions that ensure precision and consistency in every part produced.

The Importance of Precision Engineering

At the heart of custom mold manufacturing is precision engineering. Skilled engineers work closely with clients to understand their unique needs and design a mold that meets those requirements. This involves carefully analyzing the specifications of the component to be produced, determining the most efficient and cost-effective mold design, and optimizing the manufacturing process to ensure the highest quality results.

Customization and Complexity

One of the key benefits of custom mold manufacturing is the ability to create complex parts with detailed features that may be difficult or impossible to achieve with standard molds. This level of customization allows manufacturers to produce components that meet exact specifications, resulting in improved performance, durability, and aesthetics.

Durability and Reliability

In addition to precision engineering, custom mold manufacturing also focuses on durability. The materials used in custom molds are carefully selected to withstand the demands of high-volume production and ensure long-term reliability. Whether producing parts for automotive, aerospace, medical, or consumer products, durability is essential to maintaining quality and consistency in the manufacturing process.