Ultraviolet (UV) LED modules have been gaining popularity in the surface coatings industry due to their numerous benefits and advantages. These modules utilize light-emitting diodes (LEDs) to produce UV light, which is then used to cure coatings, inks, and adhesives. In this article, we will explore the benefits of UV LED modules for surface coatings, highlighting their efficiency, cost-effectiveness, and environmental sustainability.

Improved Efficiency and Productivity

UV LED modules offer improved efficiency and productivity in surface coatings applications. These modules provide a faster curing process, allowing for increased production speeds and reduced processing times. Additionally, UV LED modules can be easily integrated into existing production lines, making it simple to upgrade and improve efficiency. This increased efficiency and productivity enable manufacturers to meet growing demands and stay competitive in the market.

Cost-Effective Solution

UV LED modules are a cost-effective solution for surface coatings applications. These modules require less energy to operate compared to traditional UV LED module resulting in significant energy savings. Additionally, UV LED modules have a longer lifespan than traditional UV lamps, reducing the need for frequent replacements and minimizing waste. This reduced energy consumption and extended lifespan make UV LED modules a cost-effective solution for manufacturers.

Environmental Sustainability

UV LED modules offer environmental sustainability benefits, making them an attractive option for manufacturers. These modules are free from toxic materials like mercury, which is commonly found in traditional UV lamps. Additionally, UV LED modules produce minimal waste and are designed to be recyclable, reducing the environmental impact of surface coatings applications. This environmental sustainability makes UV LED modules an excellent choice for manufacturers looking to reduce their carbon footprint.

Enhanced Coating Quality

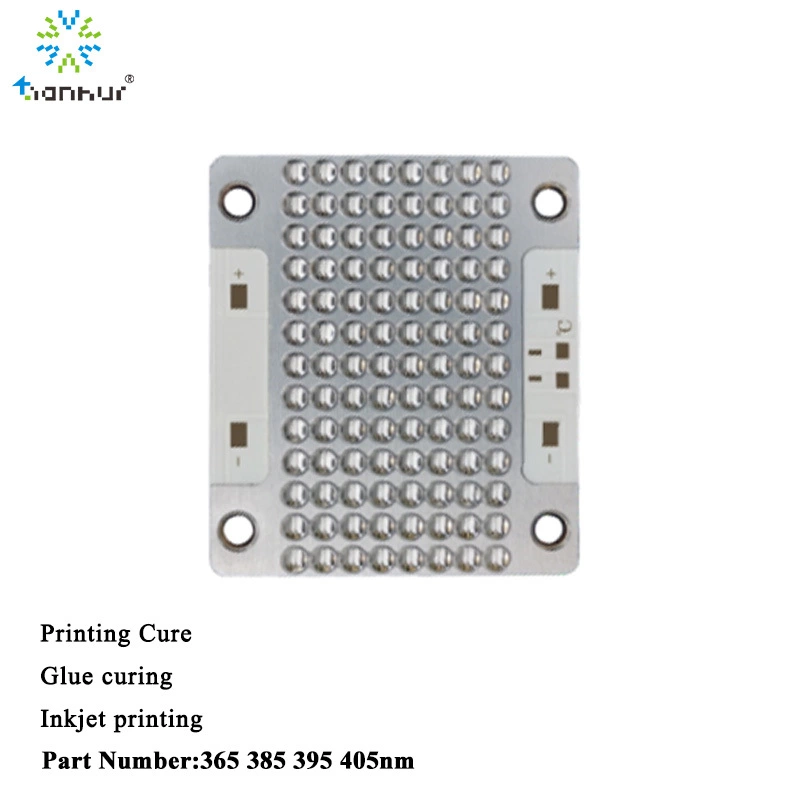

UV LED modules provide enhanced coating quality, which is essential for surface coatings applications. These modules offer a consistent and controlled curing process, resulting in a uniform and high-quality finish. Additionally, UV LED modules can be adjusted to specific wavelengths, allowing for precise control over the curing process. This enhanced coating quality makes UV LED modules an excellent choice for manufacturers looking to improve their product quality.

Increased Flexibility

UV LED modules offer increased flexibility in surface coatings applications. These modules can be easily integrated into existing production lines, making it simple to upgrade and improve efficiency. Additionally, UV LED modules can be used with a variety of coatings, inks, and adhesives, making them a versatile solution for manufacturers. This increased flexibility makes UV LED modules an excellent choice for manufacturers looking to improve their production processes.

Future Developments and Trends

The future of UV LED modules in surface coatings looks promising, with ongoing research and development aimed at improving efficiency and coating quality. Advances in UV LED technology are expected to increase production speeds, improve coating quality, and reduce energy consumption. Additionally, the development of new UV LED modules and coatings is expected to expand the range of applications for surface coatings, enabling the production of high-quality coatings for a variety of industries.

Conclusion

In conclusion, UV LED modules offer numerous benefits and advantages for surface coatings applications. These modules provide improved efficiency and productivity, cost-effectiveness, environmental sustainability, enhanced coating quality, and increased flexibility. As technology continues to evolve, we can expect to see even more innovative applications of UV LED modules in surface coatings. Whether you’re a manufacturer or a supplier, UV LED modules are an excellent choice for improving your production processes and reducing your environmental impact.