As technology continues to advance, so does the field of aseptic filling. Innovations in aseptic filling technology have revolutionized the way products are packaged, making the process more efficient and safe than ever before.

Advances in Robotics and Automation

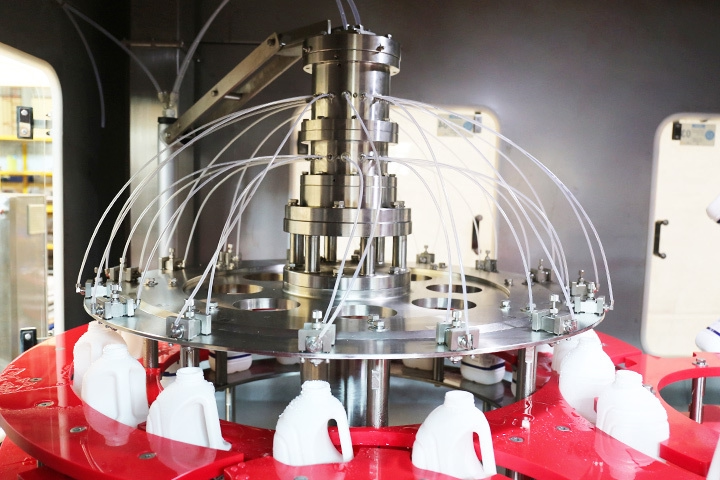

One of the key innovations in aseptic filling technology is the use of advanced robotics and automation. Robots can now perform tasks such as loading containers, filling them with product, applying caps or seals, and even inspecting the final packages for defects. This not only speeds up the production process but also reduces the risk of contamination from human error.

Closed Systems: Eliminating Contamination Risks

Another innovation in Aseptic filling line is the development of closed systems. Closed systems, also known as isolators or gloveboxes, are fully enclosed units that protect both the product and the environment from outside contaminants. This technology eliminates the need for human operators to come into direct contact with the product, further reducing the risk of contamination.

Advances in Materials Science: Improving Packaging Materials

Advances in materials science have also played a significant role in improving aseptic filling technology. New materials, such as plastics and composite materials, are now being used in the construction of packaging materials to improve their barrier properties. These materials can better protect the product from oxygen, light, and moisture, extending its shelf life and ensuring its safety.

Efficiency Improvements: Reducing Waste and Costs

Innovations in aseptic filling technology have also focused on improving the efficiency of the filling process. For example, new filling machines have been designed to minimize product waste by accurately dispensing the correct amount of product into each container. This not only reduces costs but also ensures that consumers receive the correct amount of product in each package.

High-Speed Filling Machines: Meeting Market Demands

In addition, new technologies have been developed to improve the speed of the filling process. High-speed filling machines can now fill thousands of containers per minute, allowing manufacturers to meet the demands of a rapidly growing market. This increased efficiency not only benefits manufacturers but also consumers, who can enjoy a wider variety of products on store shelves.

Improved Safety: Protecting Consumers

Perhaps most importantly, innovations in aseptic filling technology have improved the safety of products for consumers. By reducing the risk of contamination during the filling process, manufacturers can ensure that their products are safe to consume. This is particularly important in industries such as pharmaceuticals, where even the smallest amount of contamination can have serious consequences.

Conclusion: The Future of Aseptic Filling Technology

Overall, innovations in aseptic filling technology have transformed the way products are packaged, making the process more efficient and safe than ever before. With advancements in robotics, materials science, and efficiency, manufacturers can now produce high-quality products at a rapid pace, meeting the demands of today’s consumers. As technology continues to advance, we can expect to see even more exciting developments in aseptic filling technology in the future.