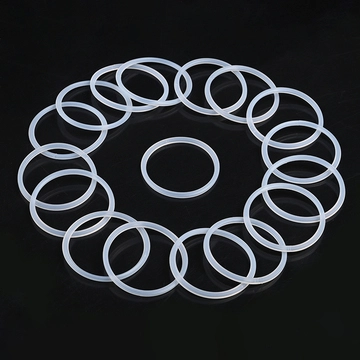

Silicone seal rings play a crucial role in the aerospace industry, providing essential sealing solutions for various applications. These rings are designed to withstand extreme conditions, including high temperatures and pressures. Understanding the key considerations for using silicone seal rings in aerospace applications is vital for ensuring safety and reliability.

Material Properties of Silicone

Silicone is a versatile material known for its excellent thermal stability and flexibility. It can maintain its properties across a wide temperature range, making it suitable for aerospace applications where temperature fluctuations are common. Silicone seal rings can withstand temperatures from -60°C to 200°C, ensuring reliable performance in various environments.

Resistance to Environmental Factors

In the aerospace industry, components are often exposed to harsh environmental conditions. silicone sealing ring offer excellent resistance to ozone, UV radiation, and moisture. This resistance is critical for maintaining the integrity of seals in aircraft and spacecraft, where exposure to these elements can lead to degradation and failure. The durability of silicone ensures long-lasting performance in challenging environments.

Compatibility with Fluids

Another important consideration for silicone seal rings in aerospace applications is their compatibility with various fluids. Silicone is resistant to many chemicals, including fuels, oils, and hydraulic fluids. This compatibility is essential for ensuring that seal rings do not degrade or lose their sealing properties when in contact with these substances. Aerospace engineers must select silicone formulations that are specifically designed for the fluids encountered in their applications.

Design and Sizing Considerations

The design and sizing of silicone seal rings are critical for ensuring proper sealing performance. Engineers must carefully consider the dimensions of the seal rings to ensure a tight fit within the assembly. Factors such as compression set, hardness, and cross-section shape can influence the effectiveness of the seal. Proper design ensures that the seal rings can withstand the pressures and forces encountered during operation.

Manufacturing Techniques

The manufacturing process of silicone seal rings can significantly impact their performance. Techniques such as compression molding and injection molding are commonly used to produce silicone seals. Each method has its advantages and disadvantages, and the choice of manufacturing technique can affect the quality and consistency of the final product. Aerospace manufacturers must select the appropriate method to meet their specific requirements.

Testing and Certification Standards

In the aerospace industry, components must meet stringent testing and certification standards. Silicone seal rings are no exception. They must undergo rigorous testing to ensure they can withstand the demanding conditions of aerospace applications. This includes tests for temperature resistance, chemical compatibility, and mechanical performance. Certification from recognized organizations is essential for ensuring that the seal rings meet industry standards.

Cost Considerations

While silicone seal rings offer numerous advantages, cost is always a consideration in aerospace applications. Manufacturers must balance the benefits of using silicone with the associated costs. High-quality silicone seal rings may come at a premium, but their durability and performance can lead to cost savings in the long run by reducing maintenance and replacement needs.

Future Trends in Silicone Seal Technology

The aerospace industry is continually evolving, and so is the technology behind silicone seal rings. Future trends may include the development of advanced silicone formulations that offer even greater performance and durability. Innovations in manufacturing processes may also lead to more efficient production methods, reducing costs and improving quality. Keeping abreast of these trends is essential for aerospace engineers and manufacturers.

Conclusion

In conclusion, silicone seal rings are vital components in the aerospace industry, providing reliable sealing solutions under extreme conditions. Understanding the material properties, environmental resistance, fluid compatibility, design considerations, manufacturing techniques, testing standards, and cost implications is essential for selecting the right seal rings for aerospace applications. As technology continues to advance, silicone seal rings will play an increasingly important role in ensuring the safety and reliability of aerospace systems